Inert Atmosphere Protection

Grinding System

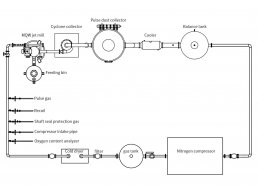

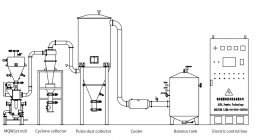

Closed loop jet mill is an ultra-fine grinding system in inert gas (nitrogen gas, argon gas, carbon dioxide) atmosphere, specially designed for flammable and explosive, easy oxidization material. Comminution is the result of impact between materials, which moved by supersonic air flow. Inert gas atmosphere allows grinding of easy oxidization products. Due to the high cost of inert gas, the system is closed loop and there are air seal devices at the entrance and exit.

System Features:

- Grinded by impact between materials, suitable for material at Mohs hardness 1-10. Low abrasion and no metal contamination. Suitable for mixed material.

- Inert gas can be changed according to materials.

- Purity of inert gas can be precisely controlled according to the requirement of product.

- Closed loop system, minimum inert gas consumption.

- Suitable for heat sensitive and low melting point material, thanks to temperature decreasing cased by gas expansion.

- Air sealing system brings accurate classifying.

- De-agglomeration for agglomeration ultra-fine powder.

- Accurate classifying thanks to high efficiency classifying rotor.

- Particle size adjustable between 2-74μm. Classifying flow distribution technology brings high grinding performance and narrow particle size distribution.

- The whole system is running under negative pressure. Dust on filter bag is cleaned by automatic impulse. Filtration rate can reach 99.99%.

- Back up filter behind dust collector to prevent dust entering air compressor.

- Automatic PLC control system for the plant. Simple operation.