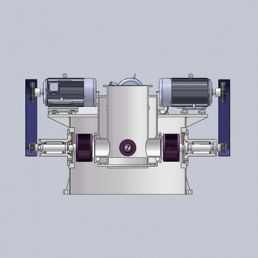

Jet Mill

After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure airflows, the materials are repeatedly collided, rubbed, and sheared to be crushed. The crushed materials rise with the suction of the fan. The airflow moves to the classification zone. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the classification wheel for collection, and the coarse particles descend to the crushing zone and continue to be crushed.

Application: Lithium iron phosphate,Ternary Material,Lithium cobalt oxide,Lithium Hydroxide,Lithium carbonate

Model & Parameters

| Material | NCM/LCO | Li2CO3 | LiOH |

|---|---|---|---|

| Particle size | D50:4±0.5μm | D50:5-6μm | D50:5-6μm |

| MQW20 Capacity | 200-250kg/h | 350-400kg/h | 250-300kg/h |

| MWQ40 Capacity | 400-500kg/h | 800-1000kg/h | 500-600kg/h |

| MQW80 Capacity | 800-1000kg/h | 1200-1500kg/h | 1000-1200kg/h |

| MQPW20 Capacity | 250-300kg/h | 2400-3000kg/h | 2000-2500kg/h |

Working principle of jet mill

The lines that we design for lithium batteriesmeet the requirements as follows:

- Achieve full ceramization, no magnetic substance.

- Overall sintering ceramic rotor up to the world's advanced level, the line speed up to 65m/s.

- Zirconia ceramic nozzle.

- Australia imports LINATEX protection,seamless protection,wear- resistant.

- Recoil gas mantle sealing disc is sintered overall.

- German standards automatic controlling technology.

- Mettler Toledo weight sensor,precise control the feeding amount.

- Automatic regulator valve, pulverizer inlet pressure controlling constantly.

- Pressure difference sensors and automatic adjusting throttle, maintaining the stability of the system resistance.

- Siemens PLC automatic control, product quality consistent and stable.

New Type Spiral Jet Mill

- Different from the ordinary fluidized bed jet mill, Spiral jet mill’s multiple nozzles to form multiple vortex, material collision grinding, high energy utilization.

- Different from ordinary spiral jet mill, the ordinary spiral jet mill has no classifying wheel control, the particle size can not be accurately controlled, the particle size changes greatly, and the consistency is poor.

- The new spiral jet mill equip with Classifier which is especially suitable for grinding single crystal ternary materials and small particle lithium cobalt oxide;

- Low energy consumption, energy saving more than 20%;

- Compact machine, convenient maintenance and small floor space

- The residence time in the grinding chamber is shorter, the surface damage is small, and the electrical performance is good

- Spiral progressive grinding force, secondary shaping of particles, sphericity is better than fluidized bed jet mill.

Model & Parameters of new type spiral jetmill

| Model | Capacity(Ternary Material) | Air consumption |

|---|---|---|

| MQPW10 | D50:3.5-4μm 100-150kg/h | 10m³/min |

| MQW10 | D50:3.5-4μm 50-100kg/h | 10m³/min |

| MQPW15 | D50:3.5-4μm 200-250kg/h | 15m³/min |

| MQW15 | D50:3.5-4μm 100-150kg/h | 15m³/min |

| MQPW20 | D50:3.5-4μm 300-400kg/h | 20m³/min |

| MQW20 | D50:3.5-4μm 300-400kg/h | 25m³/min |