Impact Mill

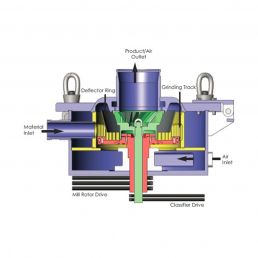

CSM series mechanical grinders are widely used in the lithium-ion battery industry, collectively referred to as air classifying mills. There are many different designs according to the different classification forms, but the principle of the grinding method is the same.

The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to the centrifugal force to collide with the grinding ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision. The material is ground, and the crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the classification wheel adjusted by the frequency conversion. The products that meet the fineness requirements enter the cyclone collector and the dust collector with the airflow for collection, and the coarse particles return to the grinding area to continue shattered.

Application: Lithium cobalt oxide, Lithium manganate, Lithium iron phosphate, Ternary Material, Lithium carbonate, NCA, Cobaltous oxide, Cobalt.

Model & Parameters

| Model | Capacity and Size of LCO | Capacity and Size of LMO | Capacity and Size of LFP | Capacity and Size of NCM |

|---|---|---|---|---|

| CSM350-VD | 100-150kg/h D50:10-15μm | 70-80kg/h D50:8-10μm | 90-100kg/h D50:5-8μm | 100-150kg/h D50:8-12μm |

| CSM450-VD | 200-300kg/h D50:10-15μm | 200-250kg/h D50:8-10μm | 180-200kg/h D50:5-8μm | 300-400kg/h D50:8-12μm |

| CSM510-VD | 600-800kg/h D50:10-15μm | 500-700kg/h D50:8-10μm | 300-400kg/h D50:5-8μm | 600-800kg/h D50:8-12μm |

| CSM710-VD | 800-1000kg/h | 800-1000kg/h | 1000-1200kg/h |

Display video of CSM-VD series

Working principle of classifier mill

The lines that we design for lithium batteriesmeet the requirements as follows:

- Whole ceramic protection,no magnetic substance.

- Optimized milling assemble,good ball shape,high bulk density.

- Humanization design,easy to change parts.

- Closed-loop system,no moisture increasing,nitrogen circle system available, extremely oxygen content.

- Machine large change to meet different capacity requirement.

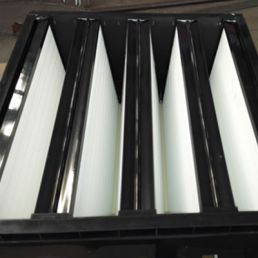

- Sintered plate filter available,filtering precision 0.1um and collecting rote up to 99.99%.

- Processing parameter memory and historical record query(intelligent control).

- Validation document available.

- Whole rotor with sintered zirconium aluminum ceramic.

- Separated zirconia ceramic gear ring.

- Customized zirconia sintered hammer.

- Whole air deflector.

- Discharge pipe upgrade to whole ceramic liner pipe.

- Imported LINATEX liner.

- No copper and zinc parts.

- Inner chamber of blower with SS304 coated PTFE.

- Return pipe anti-metal processing.

- PLC automatic control.

- Running:vibration sensor,temperature sensor.

For lithium iron phosphate,ALPA provides a special mechanical mill to meet the needs of ultra-fine, ultra-purity & big production capacity

Since 2020, benefiting from technological breakthroughs in the density of lithium iron phosphate batteries, lithium iron phosphate batteries have been increasingly favored by battery manufacturers. Its cost advantage and safety and stability have been recognized by the market again. Many mid-to-high-end models that only use ternary batteries, such as Tesla, have also begun to install lithium iron phosphate batteries.

- The grinding disc could run at speed to meet the linear velocity of 120m/s, the extremely high grinding kinetic energy enables the iron-lithium to be instantly dispersed and milled; single machine meets 1T/H-1.5T/H capacity.

- The equipment with the same hierarchical structure of jet mill meets the D50 and Dmax requirements of iron-lithium.

- Gas circulation process (nitrogen, air) to meet the water content requirements of the iron-lithium process.

- Optimize design of grinding and classification flow field, high efficiency and energy saving.

- The actual production experience of the largest Chinese impact mill (CSM1500-H) and years of accumulation and precipitation in the industry.