Grinding & Shaping Equipment

for Negative Electrode Materials of Battery

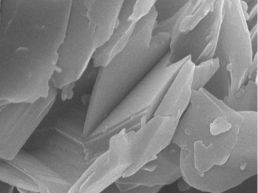

Lithium-ion battery anode materials include flake natural graphite, mesophase carbon microspheres and petroleum coke-based artificial graphite. Carbon material is currently the main negative electrode material used in lithium-ion batteries, and its performance affects the quality, cost and safety of lithium-ion batteries. In addition to raw materials and process formulas, which determine the performance of negative electrode materials, it is also one of the important factors to provide equipment and technologies such as carbon graphite milling, spheroidizing, shaping, and classifying with stable performance and high efficiency and energy saving.

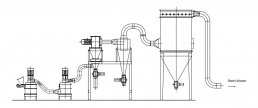

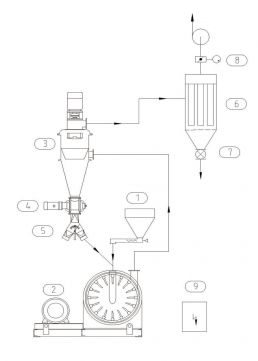

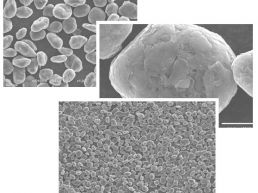

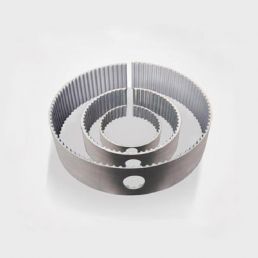

To follow the trend of negative electrode, we developed CUM Impact Mill and designed a process to realize the surface fixing with mechanical force. This system is designed to improve the shaping efficiency and performance, and meet the requirement of surface coating. CUM Impact Mills are mainly used for shaping of artificial graphite and natural graphite, grinded by CSM Air Classifier Mill. The surface of the particle is fixed under the long time, low speed mechanical force. The surface area is decreased considerably but the particle size changes slightly. This brings higher product output, narrow particle size distribution and better coating performance.

Process Description

Raw material of the secondary negative electrode

Material: Natural flake graphite, particle size ≤100 mesh, carbon content: 90%-95%

Process:Grinding-Spheroidization-Purification-Shaping & Classifying-Coating-Carbonization-De-agglomeration-Sieving-Product

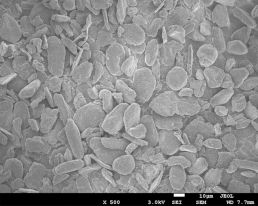

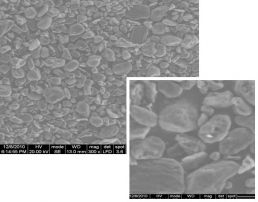

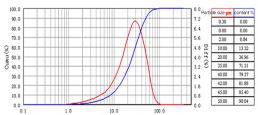

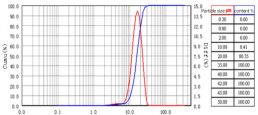

The raw material is grinded to d50: 21-23μm by the CSM710 Air Classifier Mill. The second step is to get spherical particle with size d50:19-20μm, by using CSM510 Air Classifier Mill and FW280 Air Classifier. Spherical particle is transferred to CSM410 Air Classifier Mill and FW280 Air Classifier by pneumatic conveying system, to optimize the particle appearance. By this step, the particle is in potato shape and particle size is D50: 16-17μm. Then it comes to purification. The carbon content rises to 99.95%-99.99% during this process. By following the requirement from customers, the particle is shaped, classified, coated, carbonized and packed.

Artificial graphite spheroidization process

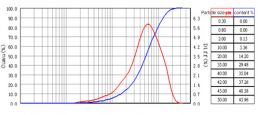

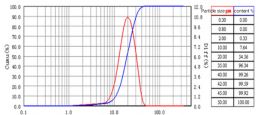

Raw materials are uniformly sent to the CSM710 special mill single set series unit through the screw feed for ultra-fine grinding. Raw material particle size is milled to D50:23-25μm fine powder, which is convenient for the next process to be spheroidized. Through 3 sets of CSM510 type spheroidizing machines equipped with FW260 high-efficiency classifiers and several sets of series unit processes, the particles are prepared into graphite powder with particle size of D50: 19-21μm, and the required qualified potato-shaped balls are obtained through the special graphite surface modification and shaping equipment.

Battery cathode material grinding & shaping process