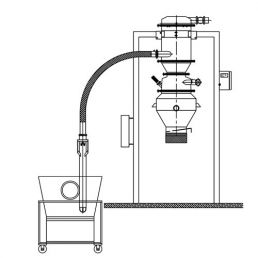

Vacuum Conveyors

AVC Vacuum Conveyer applies to transport of powder at different workshop section,so it effectively keeps from across contamination between material and environment and also worker protection. Combined different units (mill, classifier, granulator, packer, feeding silo, mixer)

- Entire closed conveying to keep free across contamination between material and environment.

- Modularize design,less moving parts,easy to dismantle,low maintain cost.

- Section structure,interface is fast clamp connection,easy to mount and clean.

- Titanium stick filter element,automatic reverse blow deashing.

- Inner surface smooth and no dead angle easy to clean.

Model & Parameters

| Model/Type | Capacity(kg/h) | Vacuum(m³/h) | Compressed Air(m³/h) | Dimensions(mm) |

|---|---|---|---|---|

| Compressed Air | ||||

| AVC-180A | <375 | N/A | 36 | 180x580 |

| AVC-200A | <525 | N/A | 60 | 210x580 |

| AVC-200B | <750 | N/A | 60 | 210x630 |

| AVC-200C | <1100 | N/A | 60 | 210x680 |

| AVC-300C | <1600 | N/A | 110 | 330x940 |

| AVC-300D | <2000 | N/A | 110 | 330x990 |

| AVC-300E | <2400 | N/A | 110 | 330x1040 |

| AVC-500E | <4900 | N/A | 220 | 500x1360 |

| Negative Pressure Source | ||||

| ZVC-200A | <625 | 126 | N/A | 180x580 |

| ZVC-200B | <900 | 144 | N/A | 210x696 |

| ZVC-200C | <1250 | 162 | N/A | 180x580 |

| ZVC-300C | <1800 | 198 | N/A | 330x1050 |

| ZVC-300D | <2200 | 216 | N/A | 330x1100 |

| ZVC-300E | <2600 | 234 | N/A | 330x1090 |

| ZVC-500E | <5300 | 390 | N/A | 500x1360 |

Remark:Testing Conditions:Material Density0.8~1.0;horizontal distance5m;vertical distance 2m;good flowability.

Filter Material:1.Ti-Metal;2.Stainless Steel;3.Coated knitted mat;4.PTFE.