On March 19th, the “14th China International Battery Technology Exchange/Exhibition (CIBF2021)” hosted by China Chemical and Physical Power Industry Association opened at Shenzhen Convention and Exhibition Center. ALPA representatives brought MQW40 fluidized bed jet mill and CSM510 -VD mechanical shredder will be exhibited, the booth is located at No. 7T062.

CIBF2021 is the largest exhibition event in the international battery industry. This year’s technical exchange will continue with the theme of “power batteries and energy storage batteries”. The latest developments in AC power batteries, energy storage batteries and various materials will be highlighted in the past two years. my country has made a series of achievements in the field of power batteries for various passenger cars, new energy buses and logistics vehicles, and in the field of new energy energy storage.

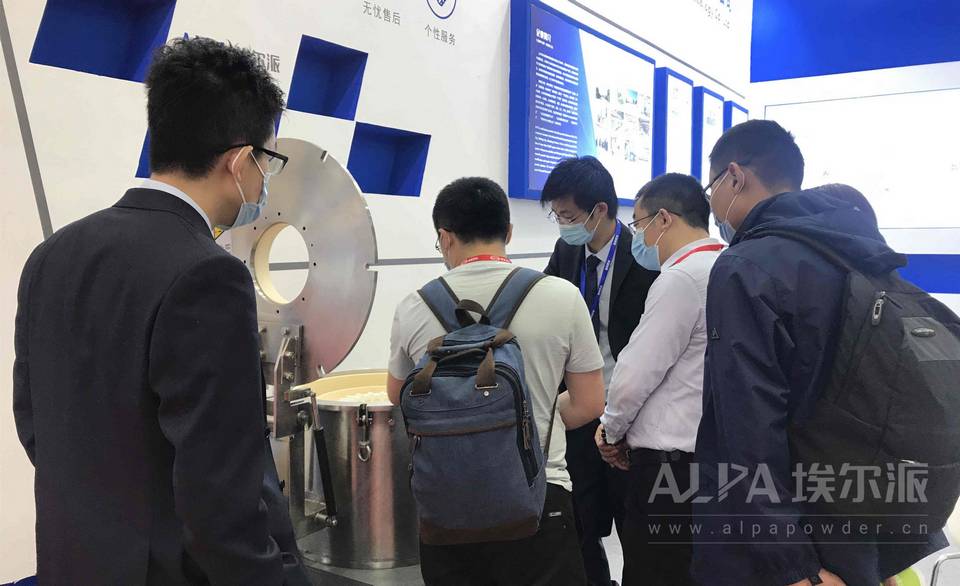

With the rapid development of mobile phones, computers, and new energy vehicles, the handling of battery materials has become the focus and difficulty of various companies. In the process of crushing raw materials, many materials are crushed and impurities, battery self-discharge capacity is reduced, energy consumption and production efficiency are not matched, product performance is poor and safety is poor, battery low voltage, etc. are all production problems faced by battery material companies.

As a well-known provider of ultrafine powder solutions in China, ALPA has developed a complete set of battery material processing solutions after years of research and development and innovation, which can provide cathode material crushing and grading, anode material crushing and shaping, battery fluid material crushing and grading, and The integrated design of the powder process technology meets the complex process requirements required for battery material processing.

The MQW40 fluidized bed jet mill at the exhibition is an innovative high-precision jet mill with a built-in precision grading wheel. It has the advantages of good particle shape, narrow particle size distribution, high product purity, less dust, and low noise. It is suitable for heat sensitivity. The crushing of volatile and high value-added materials is often used in the crushing of single crystal ternary, lithium hydroxide, lithium carbonate, lithium iron phosphate, etc.

With advanced technology and excellent products, ALPA successfully reached a strategic cooperation with a battery material company in Shenzhen and provided it with a jet mill production line for battery material crushing. The company is the world’s largest manufacturer of lithium iron phosphate batteries with the largest production capacity, and is also the world’s leading provider of solar energy and energy storage solutions. When developing new products, it proactively contacted ALPA for procurement, and ALPA successfully entered the company’s high-quality supplier system.

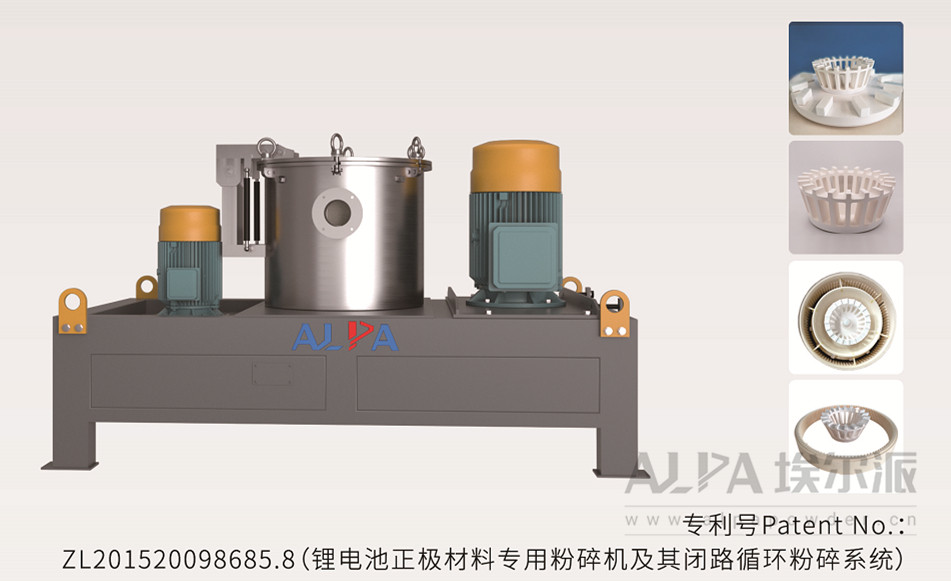

In addition, through day-to-day technological innovation, ALPA’s ceramic molding technology has also been significantly improved. The maximum linear velocity of key components such as ceramic crushing disc and classifying wheel exceeds 130m/s. In the production process, the intake of magnetic substances is less than 30PPB, the moisture increase is less than 50PPM, and the filtration accuracy of the plastic sintered plate filtering and dust removal can reach 0.1μm. The hourly production capacity of ternary materials, lithium cobalt oxide, and lithium manganate is up to 1 ton, and the hourly production capacity of lithium iron phosphate and lithium carbonate is up to 3 tons, saving 50% of energy consumption.

For example, the CSM-510VD mechanical pulverizer at the exhibition is a high-efficiency pulverizer that integrates smashing and grading. The key components such as hammer head, gear ring, and grading wheel are all made of alumina, zirconia, silicon carbide and other ceramic materials. To meet the production requirements of high-purity materials, it is widely used in the crushing of single crystal ternary materials, ordinary ternary materials, silicon carbon anode, lithium manganate, lithium cobaltate, lithium iron phosphate and other materials.

As a leader in the domestic ultrafine grinding industry, ALPA firmly believes in the power of quality and service, and has both soft and hard capabilities. It has gradually expanded the coverage of domestic and international markets. It has reached cooperation with giants in the battery material industry in many countries and has been highly praised by customers. .

Stepping on the stone leaves a mark, scratching the iron with marks. Development never stops, and backwardness will be eliminated. ALPA will definitely keep up with the pace of the times, perfectly integrate offline and online marketing networks, further expand brand strength and influence, and create brand-new results!