Lithium manganate ultrafine grinding production line of a high-tech new material company in Qingdao

The company is a well-known battery material company in Shandong Province. Learning from their peers, ALPA's solutions and equipment can meet their strict requirements for ultrafine grinding of battery material of purity and fineness. At present, 8 sets have been purchased from ALPA. The customer is still expanding production and will maintain continuous cooperation.

Raw Material:Lithium manganese oxide

Capacity:300kg/h

Feeding Size:2mm

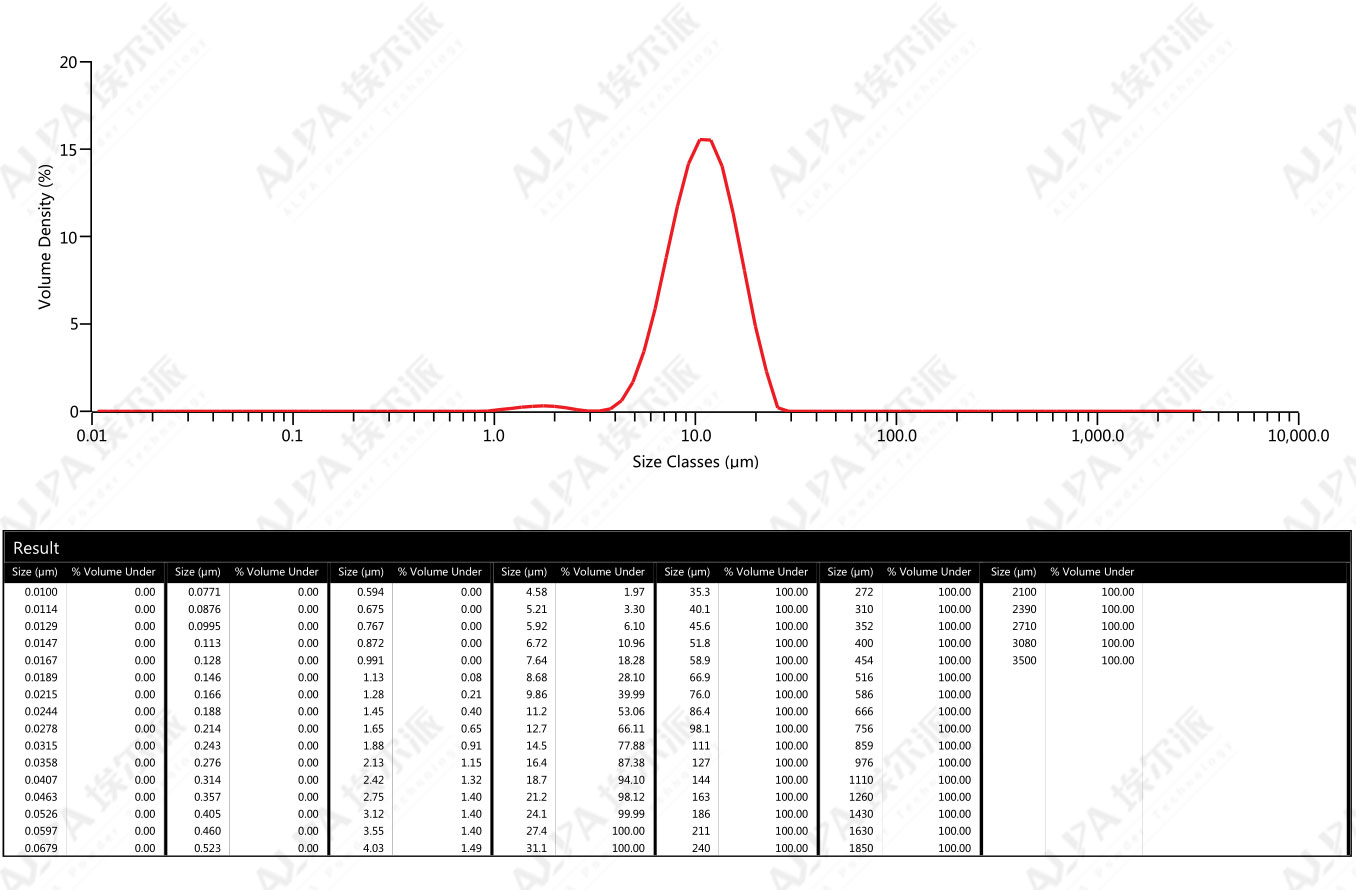

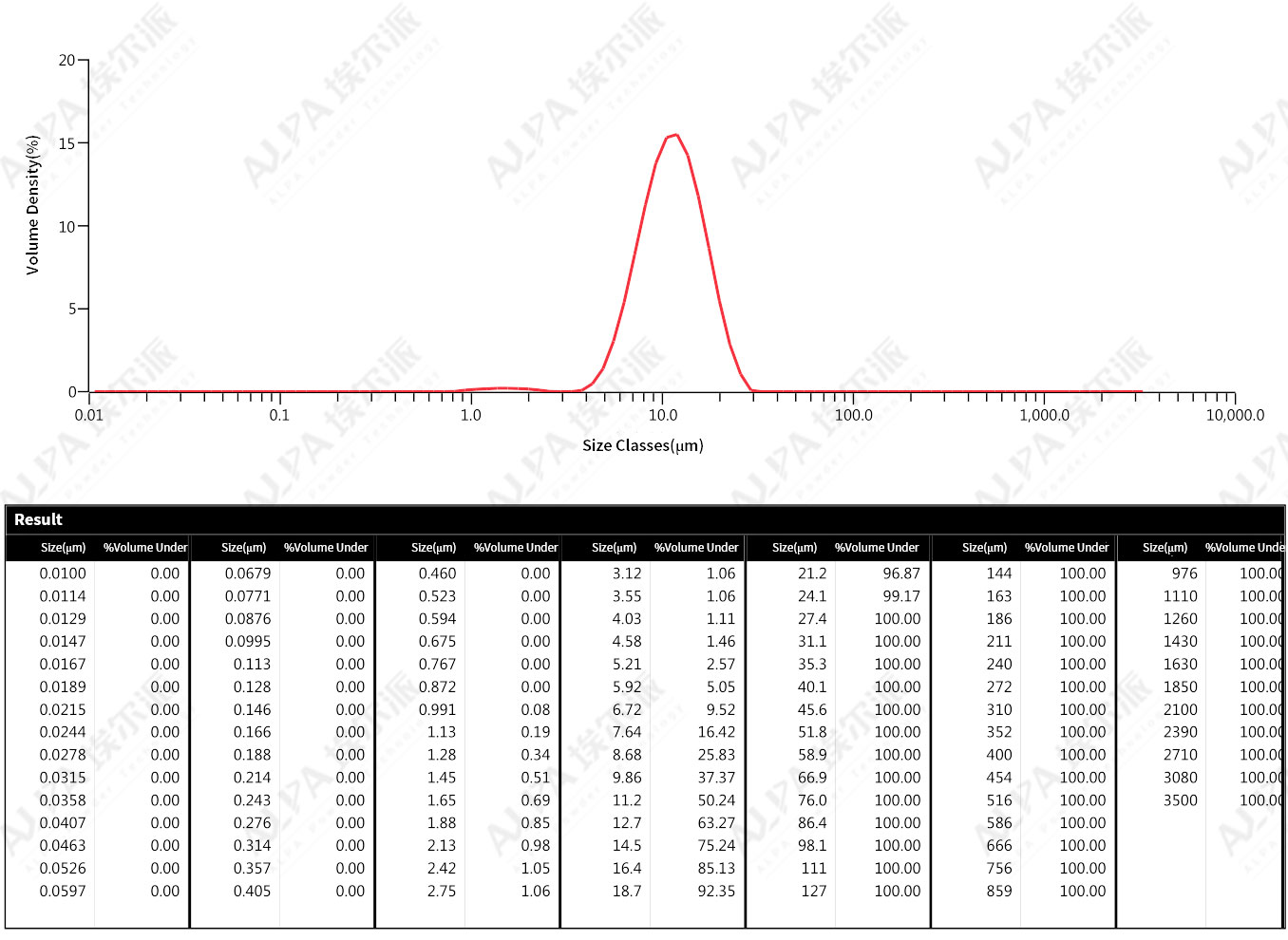

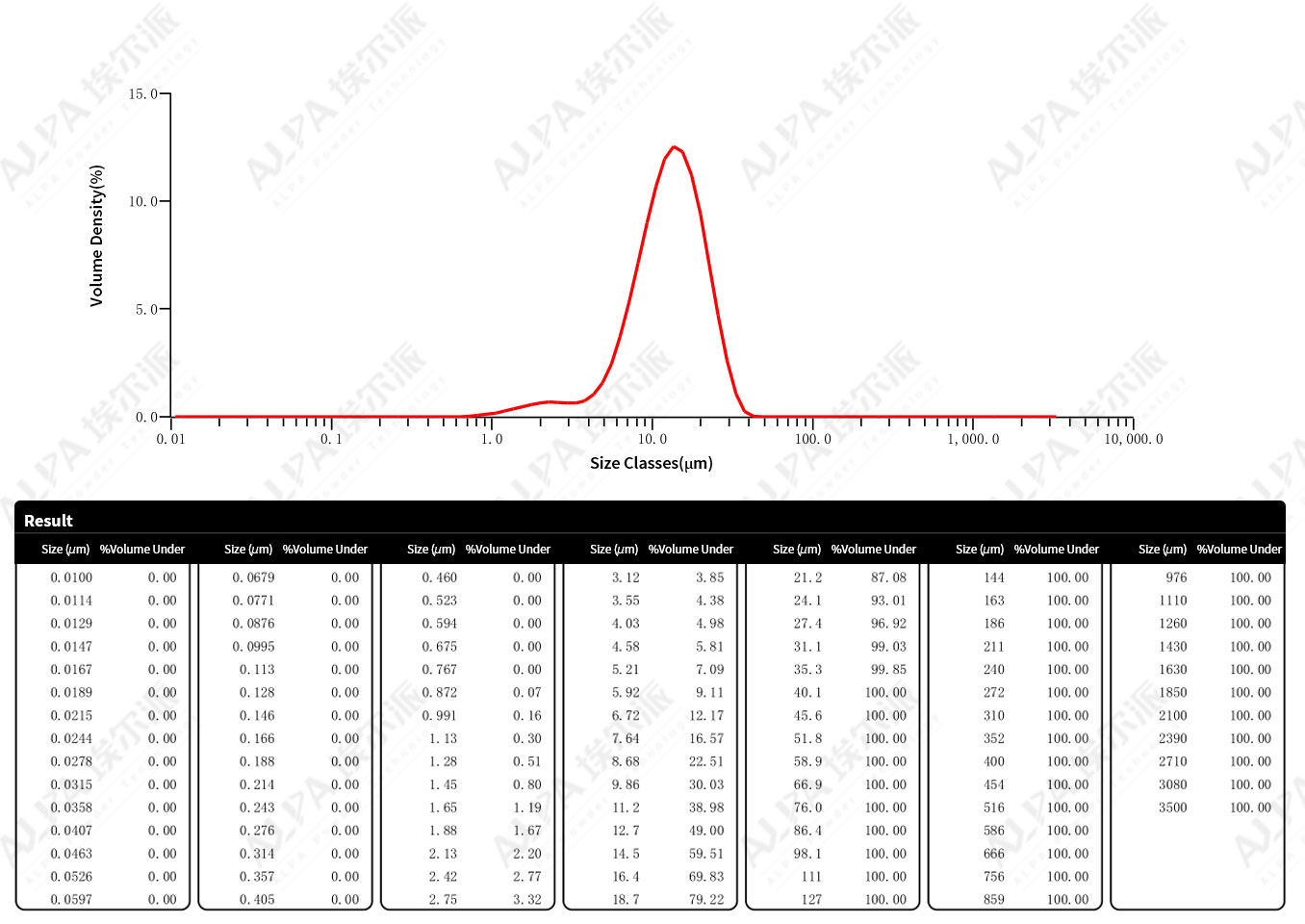

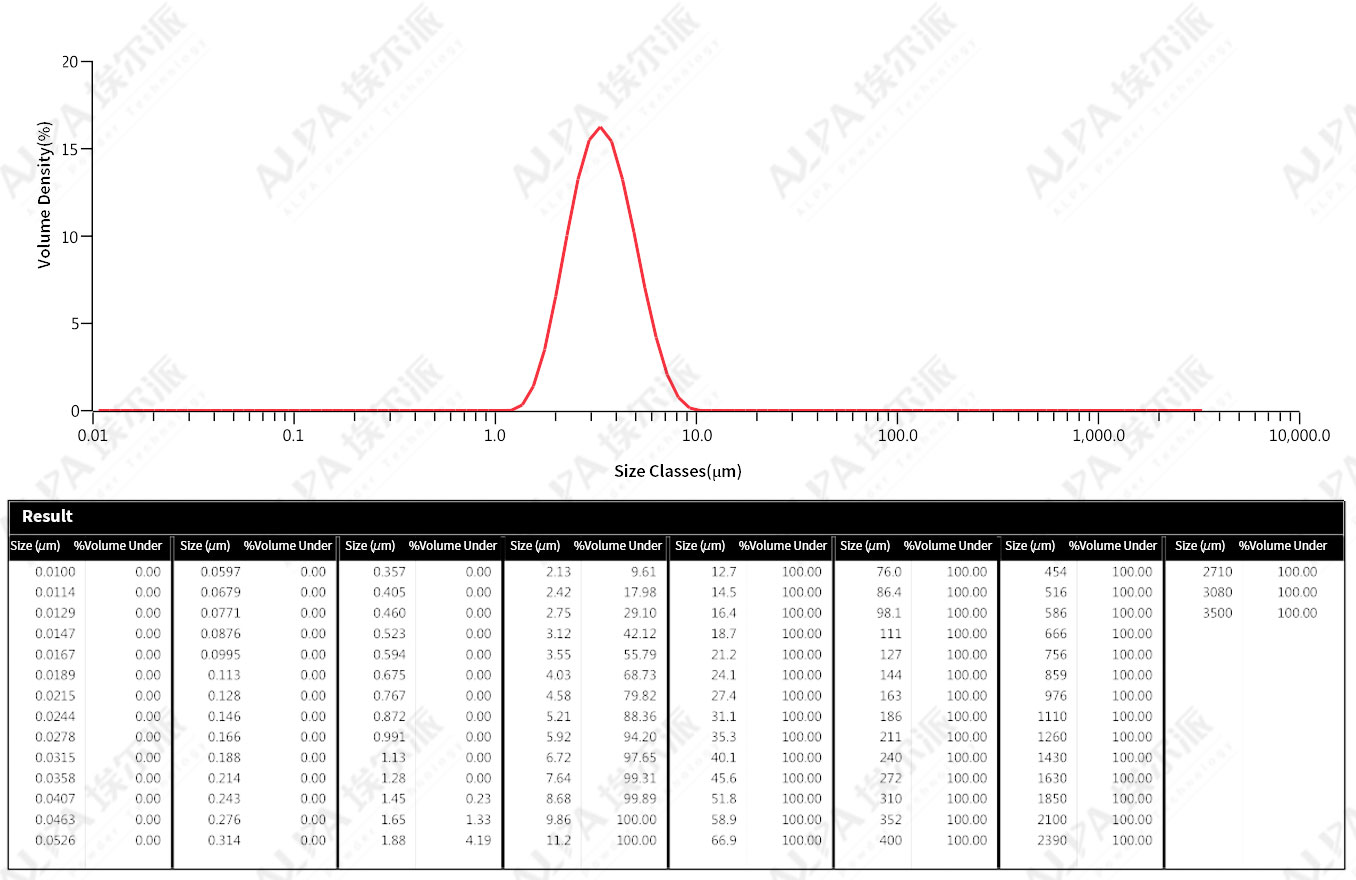

Product Size:D50:10μm

Address:Shandong

Single crystal ternary material ultrafine grinding production line of a technology company in Chengdu

The customer is a well-known new material company in the country with strong strength and has always had a good cooperation with ALPA. In the expansion project in Chengdu, almost all ALPA's ultra-fine grinding equipment has been used, and the cumulative use has exceeded 30. Now it has developed into the core customer of ALPA's long-term cooperation.

Raw Material:Single crystal ternary materials

Capacity:300kg/h

Feeding Size:1mm

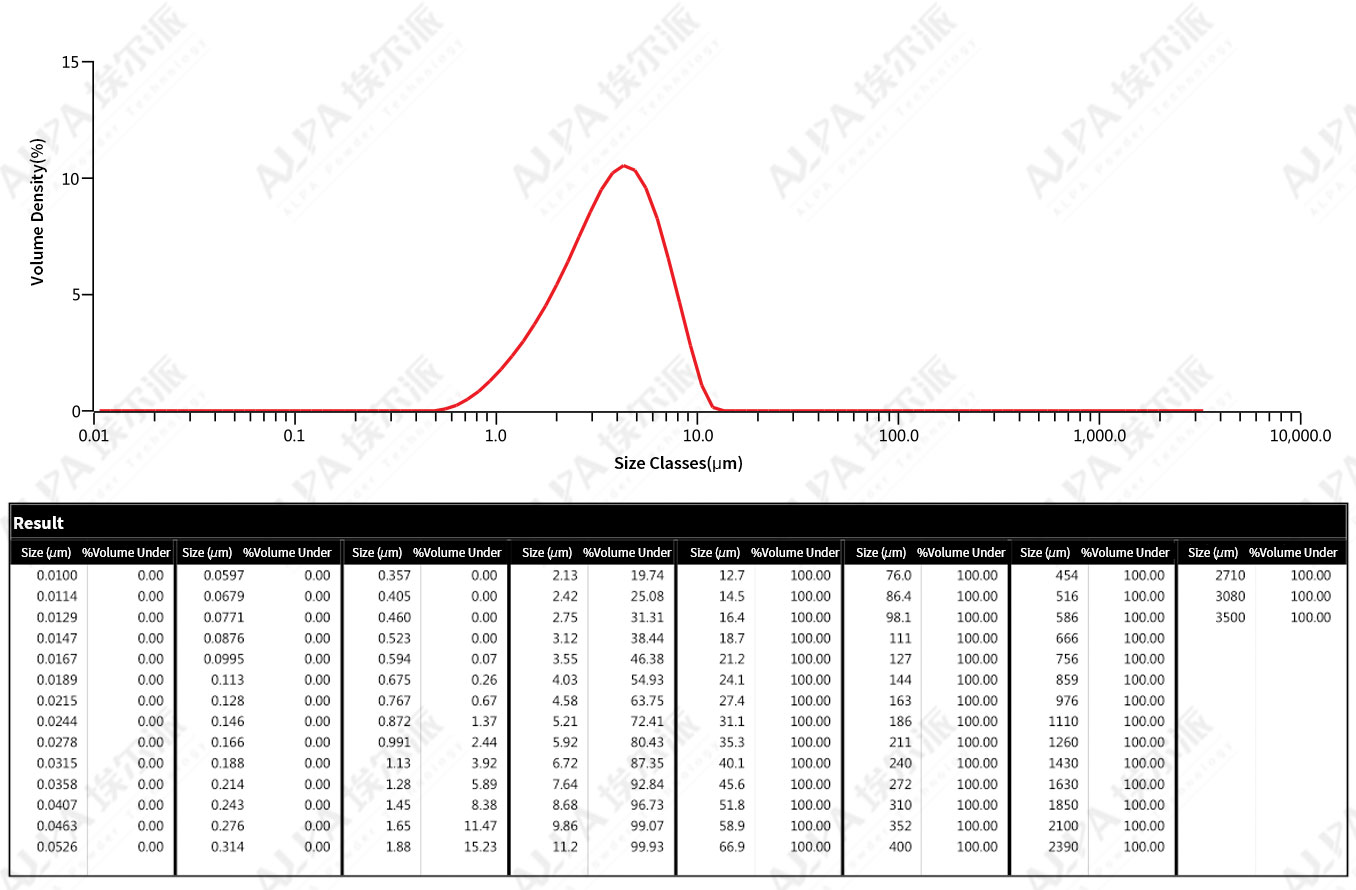

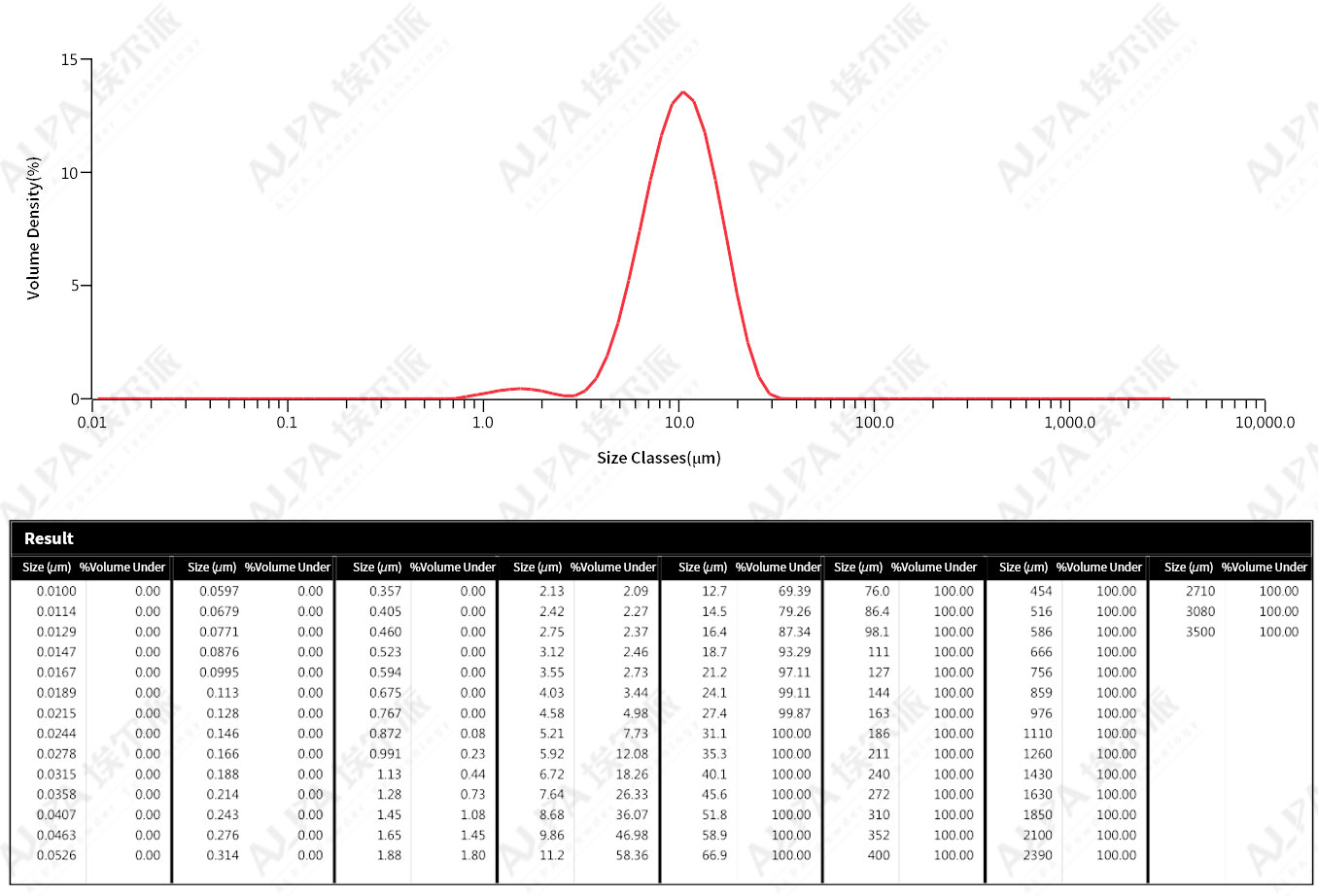

Product Size:D50:3.75μm

Address:Sichuan

Lithium cobalt oxide/ternary material ultrafine grinding production line of an energy materials company in Xiamen

This customer is a large listed company and well-known Chinese manufacturer and exporter of tungsten and molybdenum products. It has cooperated with ALPA for many years. After entering the new energy industry, he continued to use ALPA's ultrafine grinding equipment. At present, the company becomes battery cathode material company comparable to BYD, using more than 30 sets of ultrafine grinding equipment provided by ALPA.

Raw Material:Lithium Cobaltate/Ternary Material

Capacity:500kg/h

Feeding Size:2mm

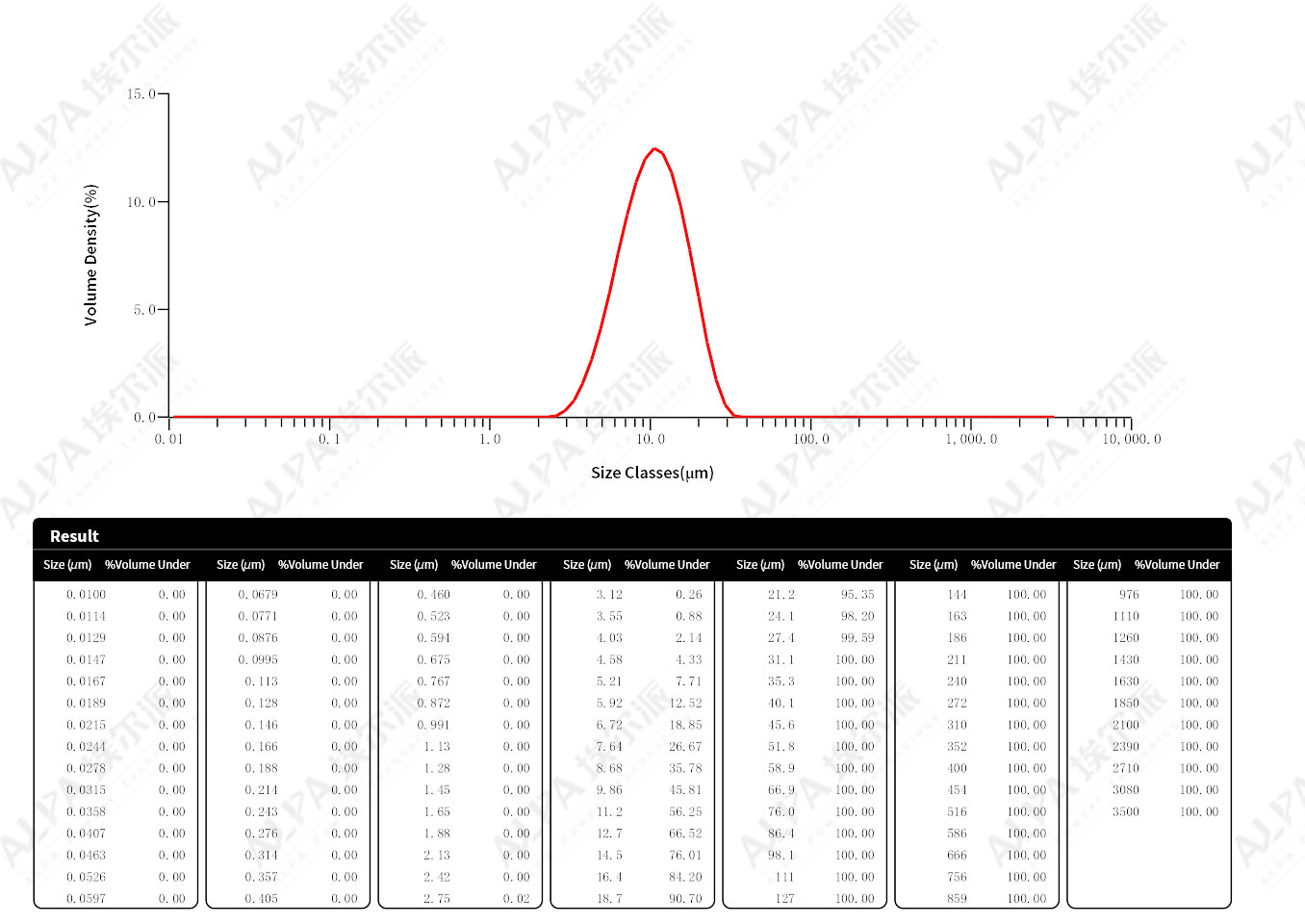

Product Size:D50:10-12μm

Address:Fujian

Lithium cobalt oxide/ternary material production line of a new material technology company in Tianjin City

This customer is a well-known company in the field of new energy and has a huge industry influence. The Tianjin headquarters has already used many ultra-fine grinding equipment. When the project was expanded, based on past experience and comparison with industry peers, it once again chose to cooperate with ALPA. At present, more than 50 sets of ultrafine grinding equipment produced by ALPA have been used.

Raw Material:Lithium Cobaltate/Ternary Material

Capacity:500kg/h

Feeding Size:2mm

Product Size:D50:10-12μm

Address:Tianjin

Ternary material ultrafine grinding production line of a High-tech company in Nantong City

This customer is a pioneer in the Chinese new energy industry and once became the main supplier of mainstream battery companies in Japan and South Korea. During the expansion project, the customer after many comparisons replaced the Japanese imported equipment with ALPA's ultra-fine grinding equipment, and its production capacity has doubled compared with previous grinding equipment.

Raw Material:Ternary Materials

Capacity:500kg/h

Feeding Size:2mm

Product Size:D50:10-12μm

Address:Jiangsu

Ternary material, Air Classifying Mill and jet mill production lines of a battery material company in Hefei City

The customer is a supplier of new energy automobile manufacturers such as King Long and Changan and the company has a market value of more than 50 billion. When upgrading the processing technology, after a comprehensive comparison of well-known ultrafine grinding equipment manufacturers in China and abroad, chose to cooperate with ALPA. At present, 4 sets of mechanical grinding equipment and 4 sets of jet mill equipment have been used.

Raw Material:Ternary Materials

Capacity:500kg/h

Feeding Size:2mm

Product Size:D50:10-12μm

Address:Anhui

Single crystal ternary material ultrafine grinding production line in a High-tech company in Hunan

The customer is a listed company in the new energy material manufacturing industry, and had a cooperative relationship with ALPA. Every time a new project is launched and production capacity is expanded, ALPA's ultra-fine grinding equipment is preferred. So far, more than 10 Lines have been used. ALPA also provided several sets of ultra-fine grinding solutions.

Raw Material:Single crystal ternary materials

Capacity:300kg/h

Feeding Size:1mm

Product Size:D50:3.5μm

Address:Hunan

Single crystal ternary material grinding production line of a company in Foshan City

This customer cooperates with a Chinese battery manufacturing unicorn enterprise and has high requirements for products. It is learned that ALPA has rich experience and good reputation in the ultrafine milling of new energy materials. When the new project was launched. After the inspection and test, ALPA provided with grinding equipment and processing solutions.

Raw Material:Single crystal ternary materials

Capacity:300kg/h

Feeding Size:1mm

Product Size:D50:3.5-4μm

Address:Guangdong

Lithium carbonate grinding production line of a lithium industry company in Jiangxi City

The customer is a high-tech company invested by a listed company in Guangdong in Jiangxi. According to peer customers, ALPA's ultrafine milling technology is at the leading level in the industry and is excellent in all aspects, so he contacted and purchased two sets of equipment. At present, the customer is still expanding production and has repurchased 10 sets of equipment.

Raw Material:Lithium Carbonate

Capacity:10000t/y

Feeding Size:60-100 mesh

Product Size:D50:5μm

Address:Jiangxi

Reliable performance! ALPA cooperates again with rookies in the battery material industry

With the development of the global economy, the deepening of the energy crisis and the increasing awareness of environmental protection, new energy industries such as power batteries and other environmentally friendly and low-carbon energy industries have also developed rapidly. The rapid growth of the field of new energy vehicles has also led to the growth of demand for power batteries. The overall performance of batteries, environmental impact, and manufacturing costs are all key factors that determine the sound development of new energy vehicles and other related industries.

The goal of the battery material industry, especially the lithium battery industry, is to develop batteries with larger capacity, lighter weight, longer life, stronger functions, and shorter charging times. However, the lithium compounds used in lithium batteries have specific particle size distribution requirements. Ultra-fine lithium powder can be obtained through ultra-fine grinding technology to improve the performance of the battery, such as higher usable capacity, longer service life, and faster The charging rate and so on.

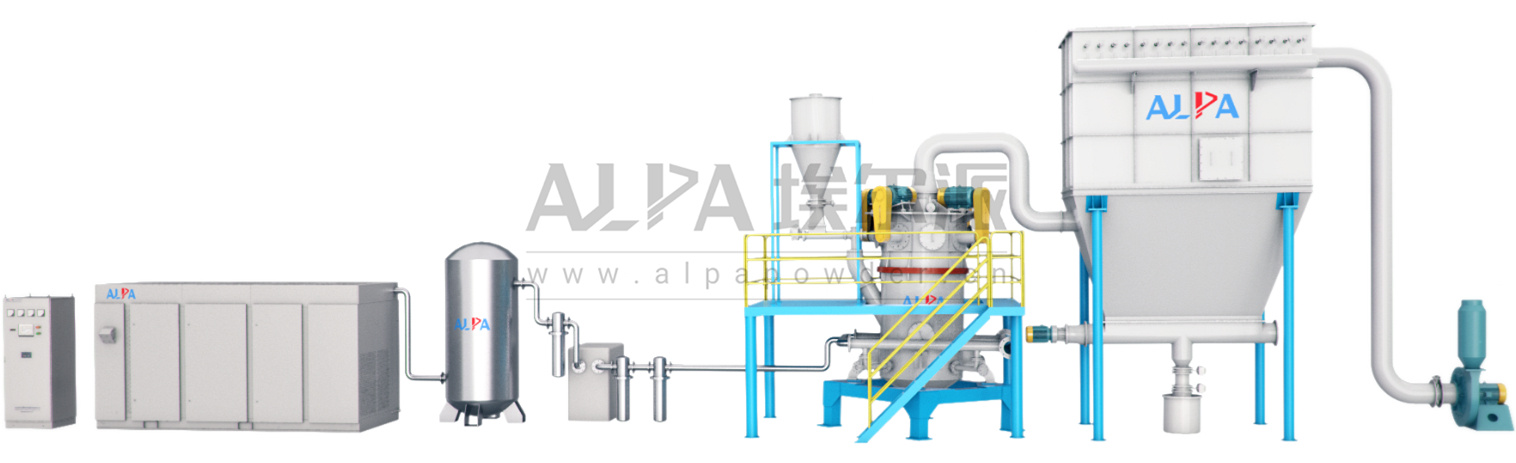

After continuous innovation and research and development, ALPA has a complete set of lithium battery positive and negative material processing solutions and equipment, including dust-free feeding, magnetic separation, ultra-fine grinding, grading, powder transportation, metering and packaging, automatic batching, intelligent control, etc. Integrated design of powder process technology. Among them, the MQW series fluidized bed jet mill is favored by users in the battery material industry. It has successively entered the purchasing ranks of battery materials and related industry giants such as a new material factory in Ningde, an energy material company in Xiamen, and an electric vehicle company in Shenzhen. Has reached a long-term strategic partnership with many companies.

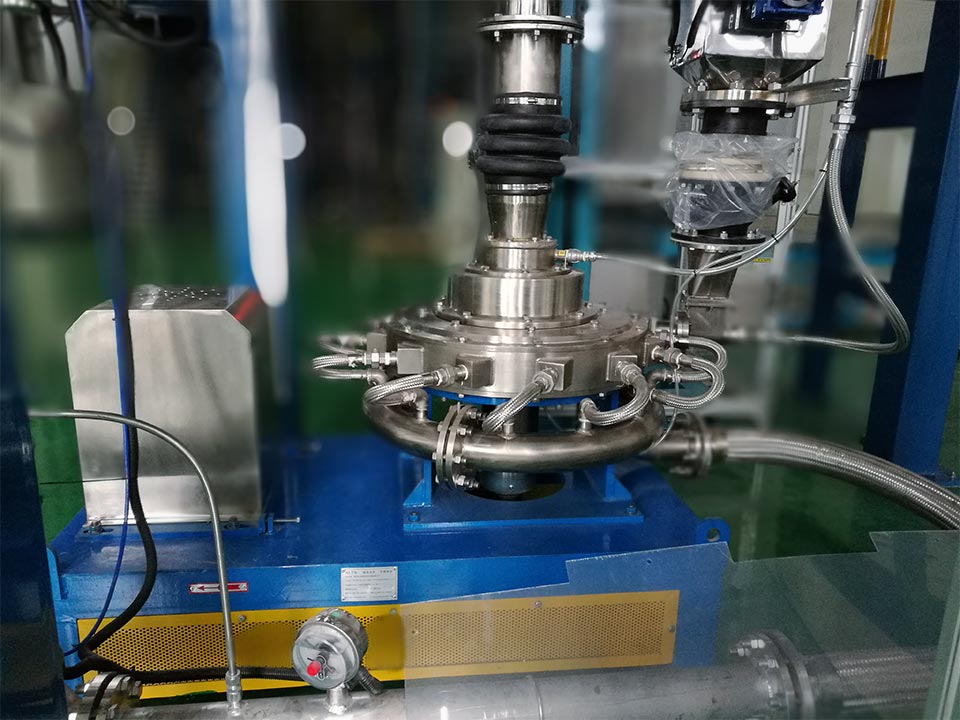

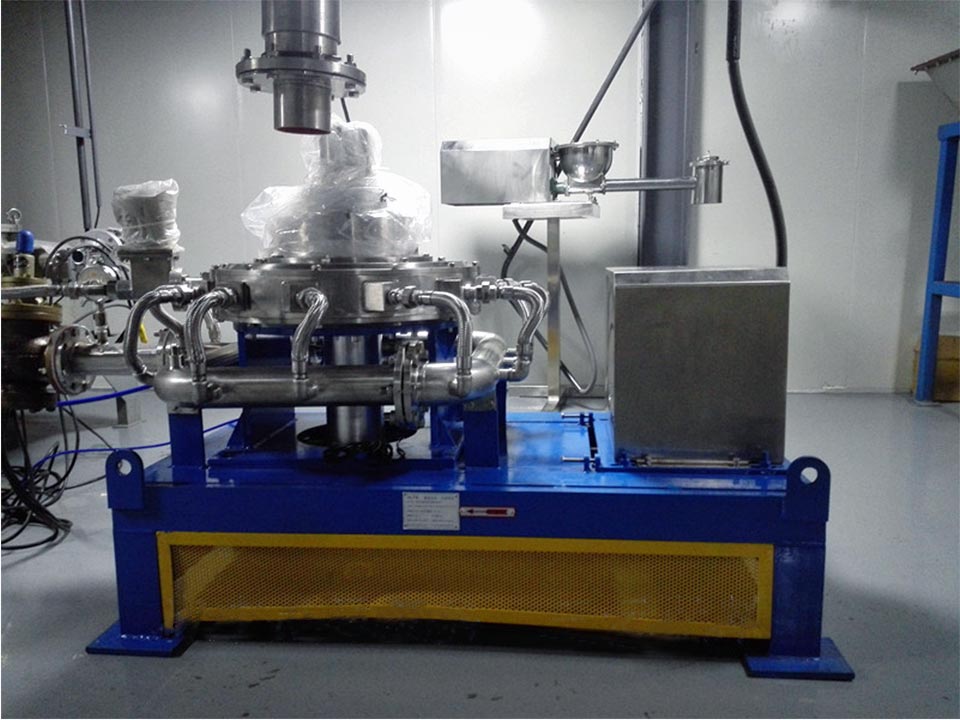

In order to meet the development goal of the green era, ALPA and a battery material company in Sichuan cooperated again to provide it with MQW100T-3 fluidized bed jet mill.

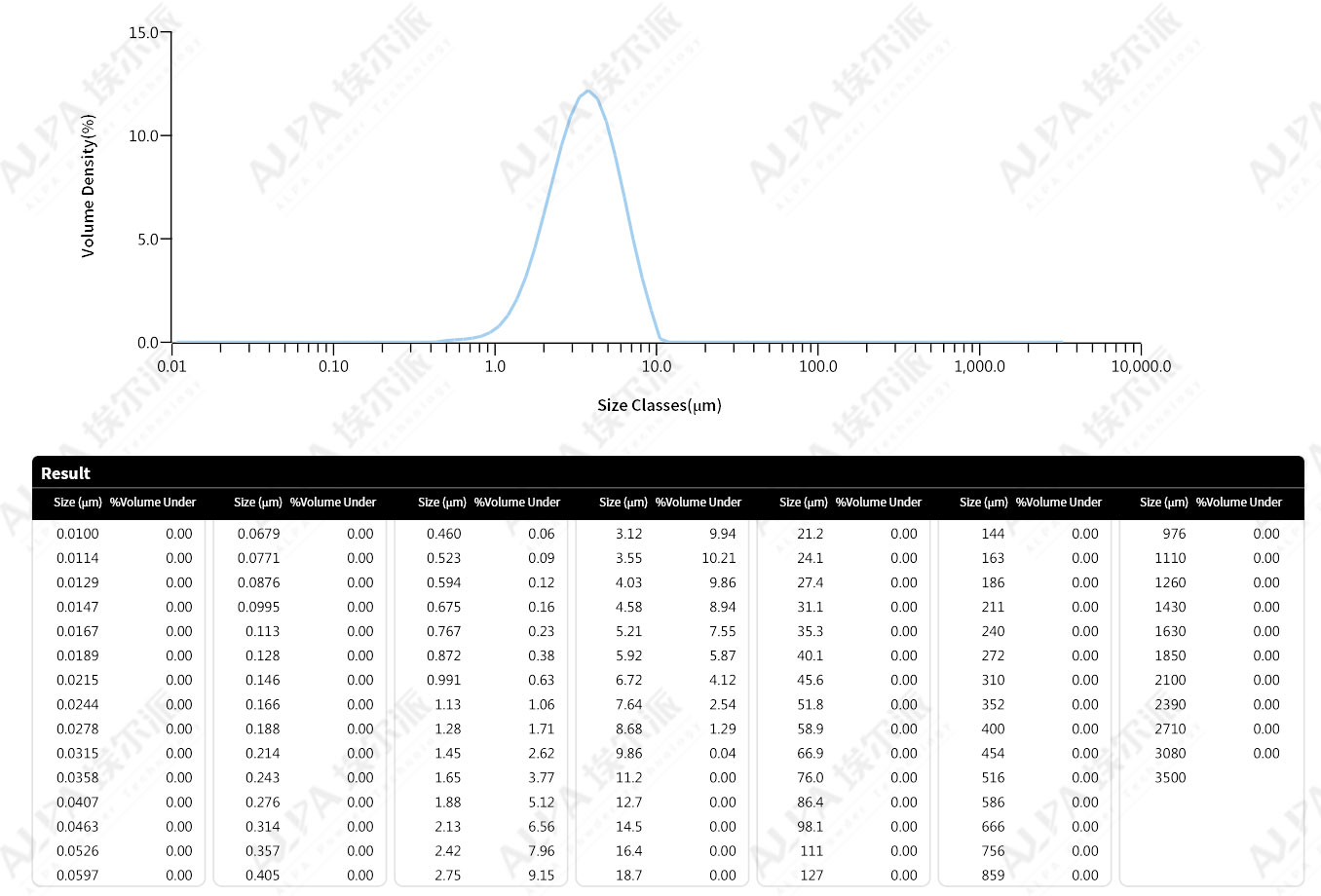

The single-machine capacity of this type of equipment is large-scale. The maximum linear speed of key components such as ceramic crushing discs and grading wheels exceeds 130 m/s. The single-machine crushing capacity of polycrystalline ternary materials exceeds 1000 kg/h, and energy consumption is saved by 50%. The finished product has good crushing particle shape, narrow particle size distribution, and high purity of the finished product. It is especially suitable for crushing materials with high hardness, high purity and high added value. The equipment can choose explosion-proof design according to the requirements to meet the crushing processing requirements of flammable, explosive and oxide materials.

The MQW series fluidized bed jet mill adopts closed-loop inert gas protection to keep the air content in the system to a minimum, minimize water intake, and the water increase is less than 50PPM. The equipment lining can select ceramic materials such as alumina, zirconia, silicon carbide, silicon nitride, etc. according to the needs of battery products, to minimize the intake of impurities, and the intake of magnetic substances is less than 30PPB. Its automatic and intelligent design concept It also guarantees the consistency and repeatability of the product to the greatest extent.

MQW series-multi-rotor-system layout drawing

In order to reduce dependence on traditional petrochemical energy, energy conservation, emission reduction, and greenhouse effect, large-scale promotion and application of battery materials such as electric vehicles will become an inevitable trend, and the overall performance and manufacturing cost of batteries will also determine their commercial viability. Important indicators.

In the future, ALPA will continue to provide ultrafine pulverization technology equipment and project solutions for the battery material industry, helping new energy companies to develop a green lifestyle.